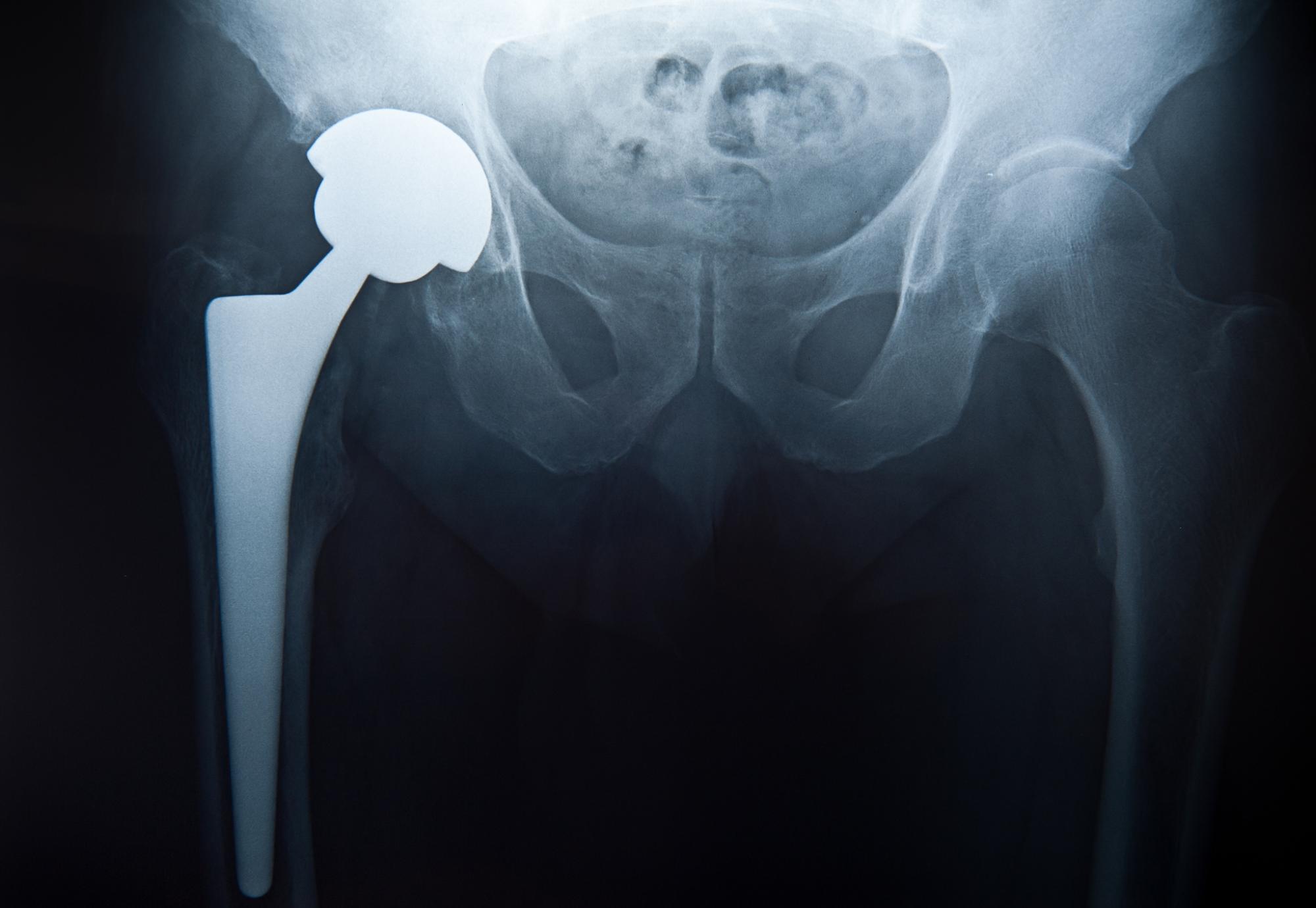

Working in partnership with South Tyneside and Sunderland NHS Foundation Trust, NHS Supply Chain was able to help make savings of more than £450,000 annually by negotiating a change of supplier for hip and knee products used in orthopaedic surgery.

The trust, which was formed in 2019 as part of a merger between City Hospitals Sunderland NHS FT and South Tyneside NHS FT, opted to undertake the orthopaedic project with support from NHS Supply Chain’s category manager and clinical engagement and implementation manager.

This gave them the skills and expertise necessary to move to a single orthopaedic provider, having previously used seven different suppliers, for their hips and knees as soon as they had merged to achieve the best value across both sites.

Decisions on the new hip and knee providers were led by orthopaedic clinicians.

As a result, the trust was able to save almost a third on their previous annual spend.

A spokesman for South Tyneside and Sunderland NHS FT said: “We worked closely with NHS Supply Chain and the suppliers on this orthopaedic project, to evaluate and rationalise the product range.

“Their expertise relating to the pricing exercise enabled the timescales to be reduced and the savings were realised earlier than anticipated.”

Emmi Mitrunen, a Category Manager specialising in orthopaedics at NHS Supply Chain, added: “It was very important that the product alternatives were clinically acceptable across both hospital sites.

“We offered access to a breadth of products and the ability to continue close working relationships with suppliers whilst remaining compliant.

“We supported the orthopaedic project by working with the clinical teams to understand which suppliers they would be willing to consider as alternatives to their current hip and knee providers.”

NHS Supply Chain was able to deliver products, expertise and pricing available under the Total Orthopaedic Solutions Framework. The standardised, compliant process was managed from beginning to end by NHS Supply Chain on behalf of the trust, including providing product analysis, organising meetings and supplier days, providing contract documentation and ensuring everyone involved was kept up-to-date with developments.